Lehigh Hanson’s Lithonia Quarry has long had a strong approach to outreach. But the pandemic forced it, like many of its peers, to adapt its approach. Its response? A focus on first responders. The quarry invited members of its police and fire departments for a recognition luncheon. Read all about it in my Good Neighbors column in Rock Products’s June issue.

Author: Therese Dunphy

Fatality Alert: Two miners killed in locomotive collision

According to the Mine Safety and Health Administration (MSHA), on June 9, 2021, two miners were fatally injured when a locomotive collided with the personnel carrier in which they were riding. The fatalities, the eighth and nine of 2021, are classified as Powered Haulage.

MSHA offers the following best practices to prevent these types of accidents.

- Install lights or other engineering controls to let miners know when it is safe to travel on track haulageways.

- Implement a communication system so that one person, who is not on any mobile equipment, has the sole authority to authorize travel on track haulageways.

- Establish and maintain effective communication protocols that require identification, location, and intended travel, between locomotives, light vehicles, and foot traffic.

- Train miners on proper traffic patterns and procedures.

Dolese donates trucks to volunteer fire departments and tech training schools

After receiving a truck chassis from Dolese Bros. Co., the Swan Lake Fire Department outfitted it with a water tank and painted it. Firefighter Nathan Roberts (left to right), Kermit Frank, and Fire Chief Dicky Wilson review the final product as it went into service.

With nearly 60 operations, including ready-mix plants, quarries, and sand and gravel operations throughout its market, Dolese Bros. Co. could easily find uses for ready-mix trucks as it cycles them out of service as drum mixers. And, it does just that; transforming some as work trucks in its quarries and selling others as used equipment for approximately $30,000. However, it also donates trucks to local volunteer fire departments and technical training programs. Read how Dolese’s donations are having a significant impact for those recipients in the March Good Neighbors column of Rock Products.

MSHA Issues New COVID-19 Guidance for Aggregate Producers

Earlier this week, the Mine Safety and Health Administration (MSHA) issued new guidance on how aggregate producers should address COVID-19 at their sites. Titled “Protecting Miners: MSHA Guidance on Mitigating and Preventing the Spread of COVID-19,” the guidance includes both recommendations and mandatory requirements. Highlights from its guidance are listed below.

MSHA recommends inclusion of the following elements in an operator’s COVID-19 prevention programs:

1. Identify a mine coordinator who will be responsible for COVID-19 issues on the operator’s behalf, and who will regularly communicate with the miners’ representative or other direct contacts for miners.

2. Identify where and how miners might be exposed to COVID-19 at work. This includes a thorough assessment of the mine site to identify potential hazards related to COVID-19. These assessments are most effective when they involve miners and miners’ representatives, because they are often most familiar with the conditions they face.

3. Identify measures that will limit the spread of COVID-19. This should include hazard removal, engineering controls, administrative controls, personal protective equipment (PPE), and other measures, prioritizing controls from most to least effective, to protect miners from COVID-19 hazards. Key examples, discussed in additional detail below, include:

- Minimize the hazard by separating and sending home infected or potentially infected people from the mine;

- Ensure miners complete isolation or quarantine as appropriate;

- Provide information and resources regarding COVID-19 vaccines;

- Implement physical distancing in communal work areas (e.g., limiting the number of miners on hoists, personnel carriers, or other transport vehicles at any one time);

- Suppress the spread of the hazard using face masks when respirators are not required;

- Improve ventilation;

- Use appropriate PPE to protect miners from exposure;

- Perform routine and enhanced cleaning and disinfection as appropriate.

4. Consider protections for miners at higher risk for severe illness through supportive policies and practices. People of any age who have certain underlying medical conditions are at higher risk for severe illness from COVID-19. Miners with disabilities may be legally entitled to reasonable accommodations (e.g., temporary reassignment to a less-populated work area or to duties with minimal in-person contact) that protect them from the risk of contracting COVID-19. Where feasible, operators should consider reasonable accommodations for certain miners identified as high-risk, such as Part 90 miners.

5. Educate and train miners on your COVID-19 policies and procedures using accessible formats and in a language they understand. Mine operators must communicate supportive policies clearly, frequently, in plain language that miners understand (including non-English language and other accessible communication methods, if applicable), and via multiple methods to miners, contractors, and any other individuals on site, as appropriate, to promote a safe and healthy mine. Communications should include:

- Basic facts about COVID-19, including how it is spread and the importance of physical distancing, use of face masks, and hand hygiene;

- Policies and procedures implemented to protect miners from COVID-19 hazards, including a method for miners to report COVID-19 symptoms, possible COVID-19 exposures, and possible COVID-19 hazards in the mine (and set forth in the operator’s COVID-19 prevention program); and

- Some means of tracking which miners have been informed and when.

In addition, ensure that miners understand their rights to a safe and healthful work environment, whom to contact with questions or concerns about safety and health, and their right to raise safety and health concerns free of retaliation. Ensure supervisors and managers are familiar with human resources policies and procedures.

6. Instruct miners who are infected or potentially infected to stay home and isolate or quarantine to prevent or reduce the risk of transmission of COVID-19. Ensure that absence policies are flexible and non-punitive. Policies that directly or inadvertently encourage miners to come to work sick or when they have been exposed to COVID-19 are strongly discouraged because they increase the likelihood of COVID-19 exposures. Operators should consider implementing pre-shift screening for miners to complete prior to entering the mine setting.

7. Minimize negative impacts of quarantine and isolation on miners. While often not practicable in a mining setting, if possible, allow workers to work remotely when their job duties allow. If this is not possible, allow miners to use paid sick leave, if available, or consider implementing paid leave policies to reduce risk for everyone at the mine. The Tax Relief Act of 2020 provides certain employers 100% reimbursement through tax credits to provide employees with paid sick leave or expanded family and medical leave for specified reasons related to COVID-19 through March 31, 2021.

8. Isolate miners who show symptoms at work. Miners who appear to have symptoms upon arrival at work or who develop symptoms during their work shift should immediately be separated from other miners, customers, and visitors, sent home, and encouraged to seek medical attention.

9. Perform enhanced cleaning and disinfection after people with suspected or confirmed COVID-19 have been in the mine setting. If someone who has been at the mining operation is suspected or confirmed to have COVID-19, follow the CDC cleaning and disinfection recommendations. This can include:

- Closing areas used or occupied by the potentially infected person for enhanced cleaning;

- Opening outside doors and windows to increase air circulation in the area, where applicable, if feasible;

- Waiting as long as practicable before cleaning or disinfecting (24 hours is optimal);

- Cleaning and disinfecting all immediate work areas and equipment used by the potentially infected person, such as offices, bathrooms, shared tools or equipment, and tables or work surfaces.

- Vacuuming the space if needed and practicable. Use a vacuum equipped with a high-efficiency particulate air (HEPA) filter, if available. Wait until the room or space is unoccupied to vacuum;

- Providing miners engaged in cleaning or disinfecting with appropriate disposable gloves. Additional PPE (e.g., safety glasses, goggles, aprons, respirators) might be required based on the cleaning/disinfectant products being used and whether there is a risk of splash. Cleaning products should be used in accordance with manufacturer’s guidance.

- After cleaning, disinfecting the surface with an appropriate EPA-registered disinfectant on List N: Disinfectants for use against SARS-CoV-2, the virus that causes COVID-19;

- MSHA’s Hazard Communication (HazCom) standards set forth in 30 CFR Part 47 remain applicable for hazard communication and PPE appropriate for exposure to cleaning chemicals.

Once the area has been appropriately disinfected, it can be opened for use. Miners who did not have close contact with the potentially infected person can return to the area immediately after disinfection.

If it has been more than 7 days since the infected person visited or used the facility, additional cleaning and disinfection is not necessary. Continue routine cleaning and disinfection, as described above.

10. Provide guidance on screening and testing. Follow state or local guidance and priorities for screening and viral testing in mines. Testing may be arranged through a company’s occupational health provider or in consultation with the local or state health department. Operators should inform miners of testing requirements, if any, and availability of testing options. CDC has published strategies for consideration of incorporating viral testing for SARS-CoV-2, the virus that causes COVID-19, into COVID-19 preparedness, response, and control programs.

Note: Performing screening or health checks is not a replacement for other protective measures such as face masks and physical distancing. Asymptomatic individuals or individuals with mild non-specific symptoms may not realize they are infected and may not be detected through screening.

11. Record and report COVID-19 infections and deaths. Operators are responsible for recording work-related cases of COVID-19 illness on their Form 7000-1 if the following requirements are met: (1) the case is a confirmed case of COVID-19; (2) the case is an occupational illness (as defined by 30 CFR 50.2(f)); and (3) the case involves one or more relevant recording criteria (e.g., medical treatment, days away from work). Operators must follow the requirements in 30 CFR 50.20 and 50.20-1 when reporting. More information is available on MSHA’s website. Operators should also report outbreaks to health departments as required and support their contact tracing efforts.

Operators also may consider recording all worker cases of and exposures to COVID-19 in a separate log for contact-tracing and training purposes. Additional information about contact tracing may be available from local public health departments.

Of significant note: MSHA recommends that operators make every effort to maintain the confidentiality of information related to a miner’s COVID-19-positive status—even in cases where it may be obvious that a certain employee has tested positive or is in quarantine.

12. Implement protections from retaliation and an anonymous process for miners to voice concerns about COVID-19-related hazards. Under the provisions of Section 105(c)(1) of the Mine Act, miners, miners’ representatives, and applicants for employment are protected from retaliation for engaging in safety and/or health related activities, such as identifying health or safety hazards, asking for MSHA inspections, or refusing to engage in an unsafe act. This includes, for example, a miner, miners’ representative, or applicant for employment raising a concern about infection control related to COVID-19 to the operator, the operator’s agent, or miners’ representative.

In addition to notifying miners of their rights to a safe and healthful work environment, operators should ensure that miners know where and how to raise questions or concerns about safety and health, and that there are prohibitions against retaliation for raising safety and health concerns or engaging in other protected activities. Also consider using a hotline or other method for miners to voice concerns anonymously.

13. To the extent possible, consider making a COVID-19 vaccine or vaccination series available at no cost to all eligible employees. Provide information and training on the benefits and safety of vaccinations. Operators may also consider permitting miners to attend vaccination appointments during their regularly scheduled shift to expedite the process.

14. Treat vaccinated miners the same as those who are not vaccinated: Miners who are vaccinated must continue to follow all protective measures, such as wearing a face mask and remaining physically distant. At this time, there is incomplete evidence about the ability of COVID-19 vaccines to prevent transmission of the virus from person-to-person. The CDC explains that experts need to understand more about the protection provided by COVID-19 vaccines before changing the recommendation on steps everyone should take to slow the spread of the COVID-19 virus.

15. Other applicable MSHA Standards: There are numerous health and safety standards that may be used to address COVID -19. Mine operators are required to abate the health and safety hazards addressed by the following standards:

- Sanitation requirements: 30 CFR 56.20003(a), 30 CFR 57.20003(a), 30 CFR 56.20008(b), 57.20008(b), 71.402 and 75.1712–3;

- Training requirements: 30 CFR 46.1-12, 48.3, 48.11; 48.23; and 48.31

- Workplace examinations: 30 CFR 56.18002, 57.18002, 77.1713, 75.360, .361, .362, .364;

- Safeguards: 30 U.S.C. 874(b) and 30 CFR 75.1403;

- Personal Protective Equipment (PPE): 30 CFR 56.15006, 57.15006, and 72.701.

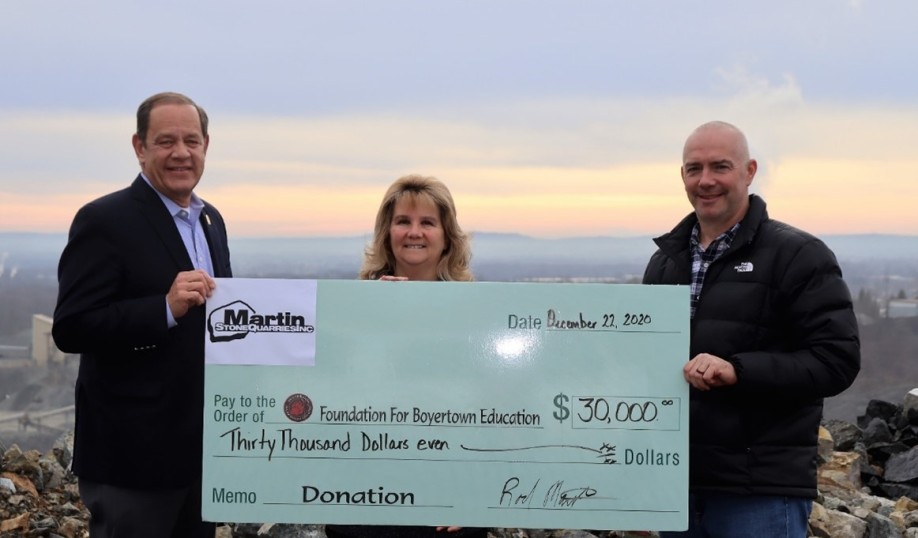

Martin Stone Quarries continues its commitment to area schools

Rod Martin, (right) president of Martin Stone Quarries and Foundation vice president, presents the company’s latest donation to the Foundation President Greg Herb and Executive Director Tessi Melchior.

Rod Martin, president of Martin Stone Quarries, Inc., recently presented the Foundation for Boyertown Education with a check for $30,000. The donation was made through the Vanguard Charitable Fund and brings the total contributed to the Foundation by Martin Stone Quarries, Inc. to $110,000 during the last five years.

Martin is a founding member and current vice president of the board for the Foundation. “The Foundation is important to us because we believe in supporting our local community – the community where we operate,” he says. “The Foundation is there to support our students in ways that would not be possible through the normal funding methods and tax revenue streams. It is with the generous help of the parents and businesses in the community that our children are given the enhanced programs and enrichment tools they need to be successful in the future.”

Read more about the company’s involvement with its local school district in the February Good Neighbors column of Rock Products.

Rogers Group Inc. purchases Reed Contracting

Rogers Group Inc. (RGI) announced that it has purchased Huntsville, Ala.-based Reed Contracting Services (Reed). The acquisition includes a quarry, sand plant, five asphalt plants, and all Reed construction assets. Founded in 1987, Reed is a provider of mass excavating, grading, underground utilities, asphalt paving, and trucking services in Huntsville. Nashville, Tenn.-based RGI is a leading supplier of crushed stone in the northern Alabama market and a provider of asphalt paving services in northwest Alabama. Combining the scope and quality of both companies, RGI will now provide seamless, start-to-finish construction and materials services to the greater Huntsville market. Managers of RGI and Reed are working diligently to ensure a smooth transition and no interruption of service to its customers.

Working with RGI to welcome more than 600 Reed employees to the RGI team, Reed’s owner and founder Mike Reed says, “Selling to Rogers Group gives me peace of mind that the values and principles I have created at Reed Contracting will live on. I am confident the family environment and growth opportunities for our people will continue for decades to come.”

“This acquisition exemplifies one of Rogers Group’s key growth strategies, which is the acquisition of well-run aggregate and construction businesses closely aligned with our core values and displaying a strong sense of responsibility to the communities where we work,” notes Darin Matson, president and CEO of RGI. “We could not be more pleased to be able to welcome the Reed employees to RGI as we combine our core strengths with theirs, to build upon the fine reputation Mike and his team have created the last 34 years.”

The acquired company will join RGI’s Southern Division led by Division Vice President Derek Roberts and operate under the direct leadership of newly appointed Vice President Anthony Garcia.

Get free industry opioid training

The opioid crisis has been making headlines for years in the mainstream media. Less known, however, is its having within the aggregates industry. Research shows that extraction workers – which includes stone, sand and gravel workers – is the leading occupation of those who have died from prescription opioids, according to data from the National Institute for Occupational Safety and Health (NIOSH). To learn more about the issue, read my article in Rock Products.

The topic of opioids is a difficult one to discuss with your employees, but help is available. Click here to access a free 45-minute training module, instructor’s guide, and participant handout designed for the stone, sand and gravel industry. It can be used in annual MSHA refresher training and meets the requirements of the health training section. Small producers may prefer a narrated version of the training, which can be found here. The training is compiled by Cora R. Roelofs, ScD, a research faculty member at the University of Massachusetts Lowell’s Center for the Promotion of Health in the New England Workplace.

Fatality Alert: Truck driver killed while attempting to adjust brakes with engine running

According to the Mine Safety and Health Administration (MSHA), on Sept. 16, 2020, a truck driver at a New Jersey sand and gravel operation attempted to adjust the brakes on his tri-axle truck while the engine was running, the automatic transmission was in drive, and the parking brake was not set. The truck moved forward and fatally injured the victim. The fatality marks the 17th of 2020 and is classified as Powered Haulage.

MSHA offers the following best practices to prevent these types of accidents:

- Before exiting, place the transmission in park, set the parking brake, turn off the engine, and activate the hazard warning lights.

- Block equipment against motion and place high visibility cones or other flagging or signage to caution oncoming traffic before working on equipment.

- Maintain equipment braking systems and repair and adjustment as necessary.

- Conduct pre-operational examinations using qualified personnel to identify and repair defects that may affect the safe operation of equipment before it is placed into service.

- Train miners on site-specific hazards.

Fatality Alert: Material Shifts on Miner Clearing Crusher

On August 18, 2020, a miner was killed while attempting to clear a material blockage. According to the Mine Safety and Health Administration (MSHA), the miner entered the cone crusher to begin work when the material shifted and engulfed him. He was extracted from the crusher and taken to a hospital, where he died the next day. This fatality, the 13th of the year, was classified as “Fall of Material.”

MSHA suggests the following best practices:

- Properly design chutes and crushers to prevent blockages. Install a heavy screen (grizzly) to control the size of material and prevent clogging.

- Equip chutes with mechanical devices such as vibrating shakers or air cannons to loosen blockages, or provide other effective means of handling material, so miners are not exposed to entrapment hazards by falling or sliding material.

- Establish and discuss policies and procedures for safely clearing crushers.

- Train miners to recognize and safely remove all potential hazards before beginning work and when clearing blocked crushers.

Fatality Alert: Dragline falls into pond

On June 13, 2020, a dragline was found submerged in 25 feet of water where a miner had been using it to remove material from a pond. Divers attempted to locate the dragline operator, and after two days the dragline was extricated from the pond. The victim was recovered from the engine compartment behind the operator’s cab. The fatality, the ninth in 2020, was the second classified as “Machinery” related.

MSHA offers the following best practices to prevent these types of accidents:

- Maintain control of operating mobile equipment.

- Keep all exits clear in cabs, including alternate and emergency exits, and make sure the doors open freely before beginning work.

- Retrofit older models of equipment with current automatic braking systems.

- Ensure all controls and brakes are set to the appropriate position for the task.

Recent Comments