Throughout the nation, aggregate producers – like so many – are grappling with the impact of COVID-19 on their businesses and employees. Producers must navigate a business environment that changes not only daily, but, in some cases, hourly. New terminology such as social distancing and essential business are quickly affecting producers.

As an industry, we must continue to protect our workers, not only from a health and safety perspective, but also an economic one. Through recent days, numerous states and local governments have ordered millions of citizens to remain at home and not go to work unless providing “essential services.” The industry quickly responded, asserting its role as an essential business.

“It is imperative that the aggregates and construction industry are allowed to continue operations to perform the work necessary to build and maintain our nation’s infrastructure,” says NSSGA President & CEO Michael W. Johnson. “State and local governments must include aggregate operations as essential to continue operation, as the aggregates industry is vital to improving public works projects that are essential for delivering much needed medical supplies, food and goods, clean water, and energy to the American people as we address this pandemic.”

The U.S. Chamber of Commerce wrote a letter to President Trump urging his administration to issue guidance on quarantine and closure orders that clarify “essential infrastructure” and “essential businesses and services.” It says the federal government should recommend exemptions including, but not limited, public works construction, construction of housing, airport operations, water, sewer, gas, electrical, nuclear, oil refining and other critical energy services, roads and highways, public transportation, solid waste collection and removal, internet, and telecommunications systems “provided that they carry out those services or that work in compliance with social distancing requirements.”

NSSGA and 22 more associations echoed the Chamber’s sentiments in a letter of their own that was sent to President Trump; Steven Munichin, Secretary, Department of the Treasury; Kevin McAleenan, Acting Secretary, Department of Homeland Security; and governors across the United States.

An “essential business”

The U.S. Department of Homeland Security considers transportation systems to be part of the critical infrastructure during COVID-19 but had not clarified – at the outset – how far down the supply chain that definition goes. This put state leaders in the position of determining what each state considered to be an essential business.

On Thursday, March 19, Pennsylvania Governor Tom Wolf issued an executive order closing all non-essential businesses within the state. Aggregates operations were not initially included on the state’s list of essential businesses.

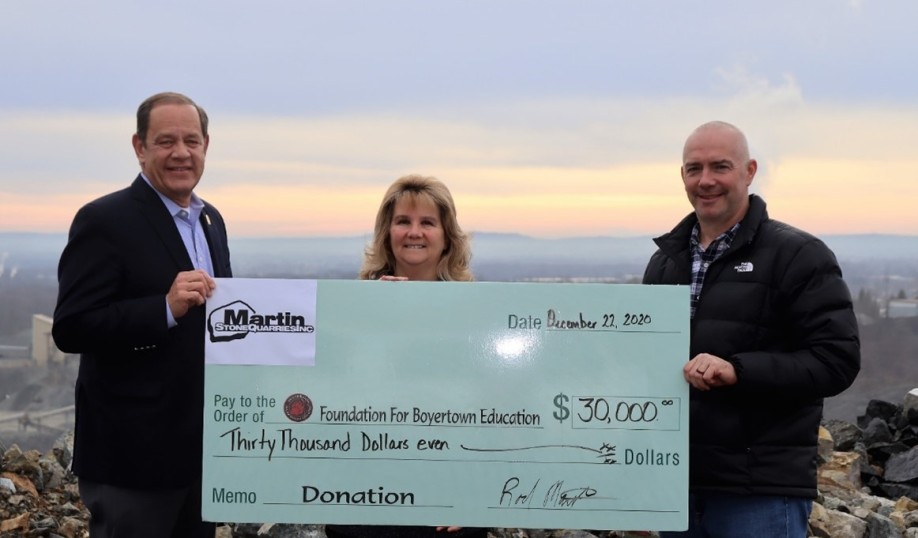

“We were very surprised to hear at 5 p.m. that we were to be closed by the Governor because we are ‘not life sustaining,'” says Rod Martin, president of Martin Stone Quarries and chairman of the board of the Pennsylvania Aggregates and Concrete Association (PACA). “Earlier in the week when they started with restrictions to help ‘flatten the curve,’ we were included on the list of ‘essential businesses.'”

It was soon all-hands on deck as state and national associations went to work to clarify the importance of aggregates role in building essential infrastructure.

Karen Hubacz-Kiley, chief operating officer of Bond Construction, emphasizes that – in the New England region – the aggregates industry provide materials necessary for the traction that improves safety of commuters traveling to hospitals, supermarkets, and other necessary businesses.

“Not including aggregates in the definition of essential businesses is short sighted and dangerous to the health and safety of those who must report to work,” she says. “With the mostly mild winter behind us, many cities and towns do not have a stockpile of aggregates should an emergency need arise for these materials.

“Nearly all individuals working in the aggregate business maintain more than 6 feet of separation as they are in different vehicles during processes that occur,” Hubacz-Kiley adds. “Aggregate operations can easily do their job and continue our necessary work while following all the CDC guidelines.”

Industry efforts were met with success on March 20 when Pennsylvania revised its list of essential businesses to include minerals production. Even more importantly, aggregate producers in other states will not face the same challenge: mineral production was recognized by the Department of Homeland Security as an essential business.

Protecting worker safety

As with other health and safety issues, their employees are of top concern for aggregates companies. They are focused on protecting their workers, even as they face the unique challenge presented by the coronavirus.

“The health and safety of our employees, customers, vendors, and communities is and always will be our top priority. During this time of concern, we are taking several precautionary steps to minimize staff contact while remaining accessible to all our partners. Temporarily, we are limiting non-employee visits to our offices unless it is critical in nature and has been approved in advance by a site manager,” says Darin Matson, Rogers Group Inc. president and CEO, in a statement on how the company is responding to the pandemic. “In addition, our sales teams and other customer-centric employees will only be visiting customer offices upon their specific request. This is to insure we create a business environment that protects the health of our employees and business partners, while offering the service and support you have grown to expect from Rogers Group.”

“Our employees have been encouraged to follow social distancing and personal hygiene recommendations. In addition, they have been instructed to stay home if they are sick, avoid non-essential travel, and avoid attending business-related events. We will continue to monitor this situation and take additional measures as needed,” Jaime Murguiro, president of CEMEX USA, says in a letter to customers.

“This is uncharted territory for all of us, and we all need to work diligently to protect our workers and customers,” says Bill Schmitz, vice president of quality control and sales at Gernatt Asphalt Products, Inc. “Keeping up to date with what other aggregate and hot-mix asphalt producers are doing is a great help.” Schmitz adds that the company’s management team is sharing information across the team via email. It is also posting best practices and notices at all plant entry points to stress working from a safe distance.

“Things are so dynamic that we are struggling to keep up as the mandates progress from federal, state, and local authorities,” he adds. “I am sure producers who operate across multiple state lines are struggling even more as the regulations are changing by the hour.”

“Martin Stone Quarries, as well as other operators, have taken additional steps like telling our employees they should not congregate in the break rooms, supplied employees with disinfectant spray for their vehicles, stopped accepting cash at our scales, eliminated the signing of tickets at our truck scales, and many more,” Martin notes.

While protecting their own employees, aggregate producers are also looking out for the communities in which they operate. For example, Winn Materials LLC, a StonePoint Materials Co., scoured its stocks and found excess boxes of N95 masks that it donated to the local Veterans Affair hospital.

“We recognize that these are unprecedented times for all of us,” the company posted on its LinkedIn page. “We at Winn Materials are committed to the health and safety of our team members, customers, our families, and our communities… It’s not much, but it’s something. We are all in this together. We at Winn Materials ask others to look for ways you can help in this time of need.”

Recent Comments